Q:How to use and maintain water-soluble cutting fluid?

A:In recent years, with the development of the machining industry, the demand for metalworking fluids and oils has been increasing. Although under the continuous development of new cutting materials, dry cutting processing mode has appeared, but the vast majority of machining still uses cutting fluid or cutting oil as lubrication medium, and due to environmental protection and economic considerations, water has a tendency to replace pure oil processing.

Water - based metal cutting fluid is almost based on mineral oil and a variety of functional agents. The synthetic cutting fluid contains no mineral oil and uses synthetic raw material as lubricant, but due to its limited lubrication property, it is mainly used in grinding.

Water-soluble cutting fluids can cause a variety of problems if not properly maintained and must be used at the recommended concentration, otherwise they can cause corrosion, odor, skin irritation, and other problems. In addition, some factors such as the hardness of the water and the contamination degree of the impurity oil are also important factors in determining the life of the coolant. In this paper, we take the water-soluble cutting fluid of Haofton Company as an example and discuss the main influencing factors.

The concentration management

Proper maintenance of coolant concentration will bring long service life and good machining performance. It is very important to use the appropriate concentration, too high concentration will give the operator skin irritation, too low concentration will cause the reproduction of bacteria, workpiece processing quality will decline, tool life will be shortened. The easiest and most effective way to detect concentration is to use a refractometer. Only a small amount of working liquid is needed on the panel of the refractometer, and the refractometer can be pointed at the bright light to read the refractive index. The refractive index times the specific refractive index of the product is the concentration of the working fluid. Sometimes the dividing line of the reading is not clear because of the mixture of oil, so you need to estimate the reading.

The concentration of the coolant is directly related to the performance of the coolant. If the concentration is abnormal, the following problems may occur: when the concentration is too high, there will be foam problems, skin irritation will increase, which will affect the paint surface of the machine tool, and fouling will easily form around the machine tool and the machine tool. When the concentration is too low, the cutting performance is not good (due to insufficient lubricity leading to tool life, machining accuracy and machining smoothness decline), workpiece, machine tool and chip rust, corruption resistance reduced (coolant service life shortened).

Water hardness

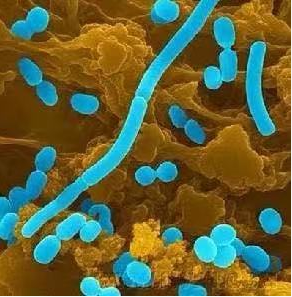

Usually the manufacturer of the metalworking liquid gives the antirust properties of the product prepared with medium hardness water and measured using standard test methods. The hardness of water is determined by the content of minerals dissolved in the water. Too high hardness can easily lead to unstable emulsion (see Figure 1), which is easy to corrode the metal. The hardness of water can be easily measured by titration or a hardness test paper.

FIG. 1 Instability of emulsion resulted from high hardness of water

The concentration and composition of the working fluid are constantly changing as the water evaporates and the mineral composition, additives or oils in the working fluid do not evaporate. The change is related to the temperature and frequency of the working fluid. The removal of metal chips and processed parts will also affect the change of coolant concentration. Each addition of water will lead to the accumulation of minerals. The specific requirements for the water quality of diluted water are shown in the table. Because these salts will lead to the corrosion of the workpiece and machine tool parts, so the requirements for working concentration will increase with the extension of the use time, in order to resist the increase of salt caused by the reduction of the corrosion resistance. The salt dissolved into the working fluid is very difficult to remove. There are only two ways to improve the corrosion resistance of the coolant, or to replace the coolant with a new one.

Microbiological management

Once mixed with water, metalworking fluids will inevitably be attacked by microorganisms. Tap water or rain water contains a variety of bacteria, fungi, molds and yeasts that can grow quickly in the presence of warm chemicals. The spread of bacteria in the air is also present. The coolant usually contains antibacterial components that are effective against microbial attack at certain levels, but these components are consumed during use.

Another method of controlling bacteria is biostable, which allows certain bacteria to exist but does not allow them to overmultiply, such as limiting the number of bacteria to less than 1×105 /ml. Emulsions are usually attacked by bacteria, while semi-synthetic ones are more easily attacked by fungi. Bacterial attacks lead to the depletion of the surfactant, which affects the stability of the emulsion and ultimately causes the separation of oil and water. Bacterial growth breaks down more acid, lowering the pH of the working fluid and leading to corrosion and skin allergies. If the coolant tank is always covered with a layer of oil, anaerobic bacteria will grow. Anaerobic bacteria convert sulfur into hydrogen sulfide gas, which smells like rotten eggs.

A typical factory day is two days off after a week's work, when the oil slick in the coolant tank needs to be skimmed from the surface as much as possible. At the same time, appropriate post-treatment can be added to control the growth of bacteria with fungicides, but it is worth noting that it is important to control the amount of addition, too much will cause skin discomfort. Fungicides are mostly formaldehyde-releasing types, and the content of formaldehyde in the working solution is controlled between 800 ~ 2000ppm when added. Skin allergies greater than 2, 000 parts per million are significantly more likely, and less than 8, 000 parts per million does not kill bacteria.

When fungi, molds, or yeasts multiply, they form a sticky skin that eventually coats the liquid surface and the interior of the machine and clogs filters and pipes. Even the addition of fungicides does not kill completely, as it is difficult for the fungicides to penetrate this layer of skin. It can only be removed physically. Add fungicides as soon as you're done, or the fungus will grow quickly. Bacteriological tests can usually be performed using bacteriological tablets.

The microorganisms that multiply in the coolant are mainly bacteria in dust, soil, yeast and so on. There are mainly several ways of mixing, as shown in Figure 2.

In fact, the mixing of microorganisms is inevitable. Therefore, in order to prevent the deterioration of the coolant, bactericide or fungicide should be added immediately when the number of bacteria in the coolant exceeds 1×105 /ml or the number of fungi exceeds 1×102 /ml.

Bacteria and fungi in the coolant can be determined by bacteria and fungi assay box. The bacteria were below 1×103 /ml, and fungus 0 was ideal. Users can also periodically add fungicides based on experience to ensure the service life of the coolant.

PH Management

The reduction of PH is one of the direct causes of cooling fluid corruption and workpiece rust, as shown in Figure 3. Therefore, often measuring the pH value of the coolant and keeping it within the range of the index value can effectively prevent the corrosion of the coolant and the corrosion of the workpiece and equipment. If the pH value is reduced, the concentration is first detected. If the concentration is normal, pH upward agent is added. If the concentration is too low, the original solution shall be supplemented first and the concentration shall be corrected. If the pH value is still too low after concentration correction, pH adjuster can be added to increase the pH value.

Miscellaneous oil and management

Generally, the coolant has a certain anti-impurity oil capability, but the mixing of a large amount of impurity oil (such as guide oil and hydraulic oil, etc.) will greatly aggravate the deterioration rate of the coolant, leading to the separation and corruption of the coolant. Therefore, it is necessary to install skimmer to remove the mixed oil timely, and record the lubricating oil supply frequently, timely find and repair the leak, so as to control the mixed oil in the minimum, which will effectively extend the service life of the coolant, thus reducing the cost of use.

Due to the strong reactivity of the new chips, it will consume too much active components of the coolant. Therefore, timely removal of the generated chips (magnetic filter or other filtering equipment must be installed) is also an important means to maintain the performance of the coolant not affected.

Conclusion

When using water-soluble cutting fluids, the active components in the coolant are usually only a few percent, and these relatively small amounts must be used for various properties. Taking this into account, the water-soluble cutting fluid is used under very harsh conditions compared to the insoluble cutting liquid.

In this harsh environment, it is very difficult to ensure the performance of the coolant over a long period of time without strict management. In addition, once metamorphism, corruption and other phenomena occur, it will cost a lot of human and material resources to return to the original normal state of use. Therefore, the daily use of coolant maintenance is indispensable. We hope that the above content can be understood and implemented to extend the service life of the coolant and reduce the probability of on-site problems.

Q:What kind and action does anticorrosive oil have?

A: 一、 The function of anti-rust oil

①、With a certain viscosity, it forms a hard or soft continuous film on the metal surface, which is separated from the air and water to prevent the rust of steel or non-iron metal.

②、All kinds of antirust oil are short-term antirust properties, antirust period can be up to about five years, but if the re-use of machinery, at any time can be used to clean the antirust oil film organic solvent, which is different from permanent antirust paint.

二、Types of anti-rust oil

①、Solvent thin layer of anti-rust oil, by the majority of enterprises of all kinds of different process for productive application, prove that the product has good anti-rust effect, at the same time easy to coating, shallow bright color, less solvent evaporation, the dosage of the province, for a third of the thick layer of anti-rust oil, thus saving more than two-thirds of the cost of production, can be used for indoor antirust between process, can also be used for packing seal rust, otherwise dehydration type rust-proof oil, can guarantee in a long time not rust.

②、Some oil-soluble waxes can be added into the solvent diluent antirust oil or ultra-thin layer of antirust oil to obtain the antirust protective film containing wax, also known as wax film antirust oil, which can obviously improve the salt spray resistance and atmospheric resistance of the oil film. However, at room temperature wax is solid or semi-solid, it is easy to precipitate out in oil products, affecting the appearance and quality of oil products, and even difficult to obtain the ideal anti-rust effect. Therefore, looking for wax with better oil solubility and significantly improved anti-rust property is the key to obtain good stability, forming film containing wax anti-rust oil uniformly. Wax film antirust oil is a solvent - type diluent antirust oil composed of film forming agent, high efficiency corrosion inhibitor and base oil. Compared with other types of anti-rust oil, wax film has the characteristics of thin film, good anti-rust and beautiful coating.

③、Water-soluble anti-rust oil with water as solvent does not contain aromatic hydrocarbon, lead and other substances harmful to human body, no three wastes are discharged during production, and the anti-rust effect is also more ideal. This anti-rust oil is easy to be coated and removed, used in the sealed parts for anti-rust, and can be cleaned with tap water. In addition, there are petroleum jelly anti-rust oil, gas phase anti-rust oil, anti-rust bag and other products play a role in part of the industry, but the anti-rust effect of anti-rust oil and the entire production process, cleaning, packaging and temperature, moisture, air pollution and other conditions are closely related to the anti-rust oil as a universal is unrealistic.

Q: How to classify fire-resistant hydraulic oil?

A: Since World War II, some technologies have evolved into safer alternatives to mineral oils. Some of them, such as PCBS, are no longer used for health and environmental reasons. The International Organization for Standardization (ISO) has now identified four major categories of fire-resistant hydraulic fluids (FRHFs), with codes for each category based on their chemical properties. HFA stands for high water content hydraulic oil; HFB stands for water-in-oil hydraulic oil; HFC represents water glycol hydraulic oil; HFDS represent synthetic or "anhydrous" types of hydraulic fluids, including synthetic esters.

HFA type hydraulic oils are called high water content hydraulic oils (HWCF), or 95/5 liquids, because only 5% of the oil is emulsified in water. Oil increases lubricity and corrosion resistance, but most of the liquid is water, so the advantages and disadvantages of water still largely represent those of HFA type hydraulic oils. For example, HFA hydraulic fluids are extremely refractory, but they must be operated with specially designed equipment. Therefore, they cannot replace mineral oils that operate in typical hydraulic equipment.

HFA type hydraulic fluids are widely used in steel mills and coal mines, where equipment is designed for HFA type hydraulic fluids. Traditional oil-based HFA types are still used, but they are gradually being replaced by synthetic fluids with better lubricity, compatibility and biological stability.

HFB type hydraulic oil is also known as emulsion. In this emulsion, water droplets are dispersed in the oil, making up most of the 60% water content. Compared with HFA type hydraulic oil, this hydraulic oil is more lubricity and rust resistance, and in some cases can achieve similar performance to mineral oil. When there is a fire, water can put it out.

HFB hydraulic fluids require constant maintenance to ensure safe and trouble-free operation. The system temperature needs to be kept low to prevent water from evaporating. Likewise, its stability needs to be checked frequently to maintain fire resistance. The HFB type hydraulic fluid is now less useful due to its cumbersome maintenance requirements and inherent instability.

HFC hydraulic fluids, or water glycol hydraulic fluids, are now the most widely used fire-resistant hydraulic fluids. The hydraulic fluid contains 35 to 45 percent water, and glycol acts as a viscosity enhancer similar to antifreeze and thickeners. Like HFB type hydraulic fluids, the water in HFC type hydraulic fluids also acts as a fire retardant, so it must be monitored and maintained at a certain level at all times. The typical characteristics of HFC type hydraulic oil are good lubricity and wear resistance. However, it will shorten the service life of ball roller bearings.

HFC hydraulic fluids can be used in most equipment designed for mineral oils, but pump speeds, temperatures, and pressures need to be adjusted. All water-based hydraulic fluids, including all HFC types, are incompressible. When running a hydraulic system, this incompressibility causes the pressure inside the system to rise very quickly. Such extreme pressure spikes can damage equipment components, so it is important to keep this in mind when choosing HFC fluids.

HFD type of hydraulic oil, this large category of hydraulic oil has several kinds, because the general does not contain mineral oil and water can be called synthetic. Phosphate ester hydraulic oils are the first member of the HFD family and are the most flame-resistant. But it is being used less and less, mainly because it is less environmentally friendly, less compatible, and more expensive. Phosphate hydraulic oils are still used in certain applications, such as aircraft manufacturing and power plants, because of their high spontaneous combustion temperatures.

Most of the phosphate ester oil is replaced by fat anti - combustion hydraulic fat anti - combustion hydraulic oil. Because it is organic ester, fatty acid ester anti-combustion hydraulic oil has a very good anti-combustion type, is now the most common TYPE of HFD anti-combustion hydraulic oil. They are well compatible with various system components, fully compatible with mineral oils and suitable for high pressure applications. In addition, due to their organic nature, the products have a good biodegradation ability, non-toxic and harmless, very environmentally friendly. Fatty acid ester flame-resistant hydraulic oils are more than twice as expensive as conventional mineral oils, so they are only used in situations where flammability and biodegradability are required.

Other types of synthetic fire-resistant hydraulic fluids are designed for specific applications. Anhydrous polyether fire-resistant hydraulic oils have long service lives and are very environmentally friendly. Silicone oils are used in key applications, but these other types of synthetic fire-resistant hydraulic oils are very expensive.

What hydraulic oil does the hydraulic equipment of high temperature open flame situation use

Fire-resistant hydraulic oil/fluid should be used in high temperature flammable situations. The fracking hydraulic oil/liquid subdivision is mainly as follows:

HFAE:Water-in-oil emulsion combustion-proof hydraulic fluid (water content > 80%)

HFAS:Water-based inflammable hydraulic fluid (water content > 80%)

HFB:Oil-in-water emulsion combustion-proof hydraulic fluid (less than 80% water)

HFC:Aqueous polymer containing refractory hydraulic fluid (less than 80% water)

HFDR:Ester type refractory hydraulic fluid

1、HFAE Water-in-oil emulsion has high specific heat, good fire resistance, excellent cooling performance, low cost, harmless to human body, and good adaptability to general non-metallic materials due to its water content of up to 80%. However, because it is aqueous solution, high steam pressure and poor lubricity, the service temperature should not exceed 50℃, and the system pressure should not exceed 7.0MPa. It is suitable for the static pressure hydraulic system of coal mine hydraulic supports and other hydraulic systems or mechanical parts that do not require recovery of waste liquid and do not require good lubricity, but require good inflammable liquid.

2、HFAS Water-based refractory hydraulic fluids, also known as high water-based fluids, usually consist of 95 percent water and 5 percent water-soluble chemicals. It does not burn, has no compressibility, has high heat capacity and thermal conductivity, and has good cooling effect. The operating temperature of the system is usually lower than that of the oil system. Low viscosity, quick deposition of dirt, low price (only 1/5-1/10 of the cost of mineral oil), non-toxic, pollution-free, easy to handle. The best use temperature in 4 ~ 50℃, too low temperature may freeze, too high, evaporation too fast. The lubricity of water is poor, so it should not operate at a system pressure higher than 7.0MPa. In addition, it in addition to and aluminum, magnesium, lead, zinc, galvanized steel (material), cadmium metal materials do not adapt, and cork, paper, butyl rubber, leather, most coatings and coatings are not adapted. Attention should be paid when using. It is suitable for low pressure hydraulic system and metal working machine which need inflammable liquid.

3、HFB Oil-in-water emulsion is composed of 60% mineral oil and 40% water. Fine water particles are dispersed in the continuous phase of mineral oil. Water is the fire-resistant component. Compared with mineral oil, oil-in-water emulsion has a relatively low lubrication performance, which limits its use in high pressure systems. Due to the water content and high vapor pressure, the maximum temperature it can use cannot exceed 65℃. One of the main problems of oil-in-water emulsion in use is its stability. Long-term standing, high temperature and pollution will cause phase separation, which will accelerate the premature damage of the pump. The main advantage of oil-in-water is that it can use the same non-metallic materials as mineral oil, including seals, hoses and paints. It is suitable for general metal materials except magnesium. Suitable for medium pressure and high pressure, high temperature and inflammable system in metallurgy, coal industry, etc.

4、HFC Water-glycol liquid is also an anti-fire hydraulic fluid with water as the anti-fire component. It consists of 30-55% water, 25-45% ethylene glycol, glycerol or its polymer, water-soluble thickener, antiwear agent, antirust agent, anti-foam agent and so on. The liquid has excellent flammability, high viscosity index, good stability and fluidity, and is a transparent true solution. It can use the same sealing materials and hoses as mineral oil, but is not compatible with zinc, cadmium, magnesium, silver and untreated aluminum, and cannot use leather or cork. Can soften ordinary paint, only on epoxy or vinyl paint. Glycol has a certain toxicity, should be prevented from entering the mouth, but does not harm to the body. Suitable for low and medium pressure hydraulic systems in metallurgy and coal industries.

5、HFDR Ester type synthesis of fire - resistant hydraulic fluid. This kind of anti - combustion hydraulic fluid has high spontaneous ignition point, low volatility, good anti - combustion, lubrication performance is comparable with the best mineral oil. It can adapt to most metal materials. However, due to its large polarity, strong solubility, usually mineral oil can adapt to the general non-metallic materials such as nitrile rubber, neoprene, asbestos rubber sheet, polyvinyl chloride plastic, plexiglass and vinyl paint it does not adapt, must be carefully selected to match the material. Ester type refractory hydraulic oil mainly has two kinds, one is phosphate type, the other is fatty acid ester type, phosphate ester type has a long history, the use temperature range is -50 ~ 135℃, suitable for metallurgy, thermal power generation, gas turbine oil and other high temperature and high pressure operation of the hydraulic system. However, it has been gradually replaced by fatty acid ester type inflammable hydraulic oil due to its poor hydrolysis stability, highly toxic hydrolytic products and great environmental hazards.